The Technology of Laser Cutting and Its Advantages

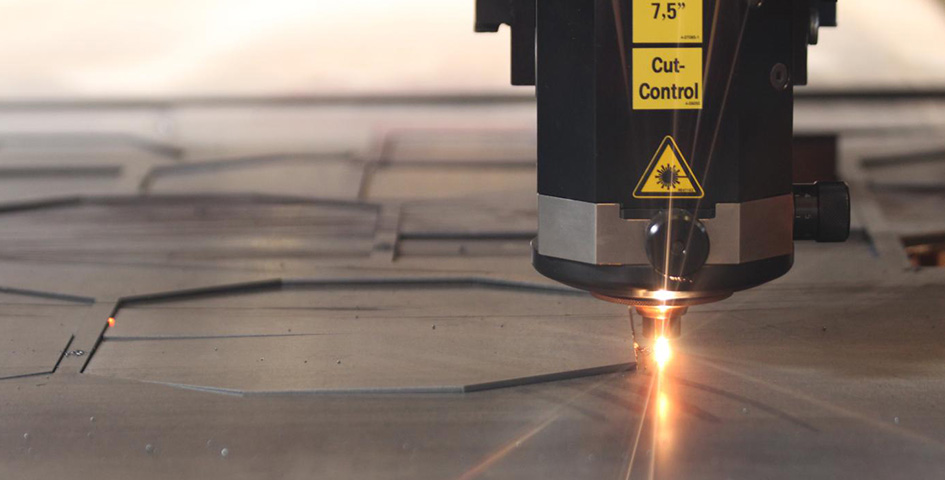

Utilizing laser to cut materials is known as laser cutting and is typically utilized by Industries. How does this function? A PC is utilized to coordinate a powerful laser for the material to be cut. When the laser is utilized on the material it normally melts or consumes and a top notch surface completion is created. These are otherwise called Industrial laser cutters and they are utilized to cut level sheet materials.

There are various types of laser cutting:

CO2 laser is utilized for cutting, exhausting and etching. It is utilized for Industrial cutting of material. The CO2 lasers is utilized be going a current through the gas blend or utilizing Radio Frequency energy.

The Radio Frequency (RF) technique is more famous as they are not inclined to issues, for example, terminal disintegration which is predominant in different strategies. The gas stream can likewise influence execution.

The neodymium Laser (ND): is additionally utilized for exhausting. However, here high energy beats are utilized utilizing a low reiteration speed.

The Nd-YAG laser: here exceptionally high energy beats are utilized for exhausting and etching as well as managing.

Laser cutting is exceptionally fruitful in light of the fact that it is a neater, cleaner and quicker approach to cutting when contrasted with the customary strategies for cutting. The laser pillar is exceptionally exact and speedy and is liked over the customary approaches to cutting as a portion of the materials are truly challenging to cut. High energy is utilized to do this specific approach to cutting. It is likewise the most practical technique for cutting high accuracy parts. Since the parts a laser cut time is saved as parts don’t should be cut physically.